4X4 drivelines have a big job asked of them, as there are so many components that fall under the driveline banner. The scary thing is each part bolted to your vehicle is just as important as the next. In-fact, I’ve been stranded on the side of the road thanks to a $35 universal joint that decided it didn’t want to play along. And let’s just say it’s a long walk to the auto-parts shop for a $35 part…

Knowing how something works is the best step forward when it comes to preservation. Let’s take a closer look at what makes your four-wheel drive, well… a four-wheel drive.

But do you understand the mechanics of how your vehicle gets from the driveway to the tracks?

AXLE SHAFTS

WHAT ARE THEY: Axles are responsible for transmitting drive from the vehicle’s differential centres to its wheels. Also known as axle shafts, the factory fitted items are in most cases constructed from a material known as hardened 1040-axle steel, which is a compromise between strength and ductility (and price, no-doubt).

WHY THEY BREAK: Generally the splines (where the axle meets the diff) on an axle shaft will twist first, however if driven too hard for too long, or if shock-loaded (jumping on hard surfaces), the axle shaft will shear. In some cases, the factory axles are in fact the weakest point in the driveline. This causes major issues, as it can take specialised tools to remove the broken shaft stuck form the differential centre.

HOW TO UPGRADE THEM: Aftermarket axle shafts with serious amounts of engineering! We’re talking about features like larger shaft diameter, rolled axle splines and high-grade chromoly construction, using material grades such as 4140 or 4340 (we’ll get to this later). This creates a stronger, more durable axle that is less likely to break under stress.

WHAT’S THIS CHRO-MO BUSINESS?

Chromoly is strengthened steel that has been blended with chromium and molybdenum. It is lighter, however it retains its high strength properties, making it perfect for roll cages, aircraft and even bicycles. The benefit of chromoly for driveline applications is that it can be hardened and quenched (via heat treating or induction hardening) for additional strength. This means less weight in a stronger product. There are many different grades of chromoly, and it pays to do your research before someone tells you that their ‘chro-mo’ axles are better than another.

CLUTCH

WHAT ARE THEY: Clutches provide drive from the engine to the transmission by utilising high-friction materials to provide a bind. They also allow for gear changes by disconnecting the drive from the engine and gearbox, which are linked in their simplest form by input and output shafts.

WHY THEY BREAK: Fitting bigger tyres, and driver error by riding the clutch (holding it on he friction point) creates additional heat that destroys clutches. Another consideration is water or mud entering the clutch assembly after or during water crossings. This makes an absolute mess of the internal components, and can leave you without any drive. Increases in horsepower will also push a clutch to its limit, so if a turbo upgrade or engine conversion is in your foreseeable future, consider a clutch upgrade to a stronger unit with higher clamping pressures at the same time.

HOW TO UPGRADE THEM: Heavy-duty clutches are available with higher clamping pressures and better abrasive materials to minimise slipping and wear. Slipping causes heat, and heat is the biggest killer of clutches. Also budget to have your flywheel machined when changing your clutch, and if you own a vehicle with a dual mass flywheel, consider having it upgraded to a solid flywheel for simpler maintenance, reliability and strength (at the small price of a less refined pedal feel).

CV JOINTS

WHAT ARE THEY: CVs provide drive to front wheels while allowing them to turn through corners. Generally considered the weak link in a driveline, breaking a CV can put an end to a trip quite dramatically. Anyone who has broken one will know the sickening BANG! Click…click…click sound that follows.

WHY THEY BREAK: Driver error and incorrect suspension modifications are the main reasons. Either using too much steering lock while accelerating, shock loading the driveline by jumping the vehicle, or running too much lift with an IFS vehicle. This extends the CVs past their safe operating angles, and will put an end to your day on the tracks pretty quick.

HOW TO UPGRADE THEM: Use aftermarket chromoly CV joints if they’re available, constructed from 4340-grade forged chromoly. Be careful though, as this grade of chromoly, while stronger than stock, is actually a softer material. This means they will wear out faster if daily driven, which is especially true in a full-time four-wheel drive as the CV joints are constantly rotating and providing drive.

TRANSFER CASE

WHAT ARE THEY: Think of a transfer case as a centre differential, sending drive to the front and rear diffs when selected (or required). They also offer reduction gearing (low range) for negotiating steep or technical terrain.

WHY THEY BREAK: Lack of maintenance, and contaminants such as water entering through the breather tube (this is why we install extended diff breathers) are major culprits when it comes to transfer case damage. Too much power will also destroying internal gears and a lack of use can cause damage to your transfer case, too. External linkages that are connected to the shifter mechanism of the transfer case can also sometimes rust, bend or become dislodged.

HOW TO UPGRADE THEM: Stronger mounting arms to reduce movement, low-range reduction gears for slower crawl-speeds, replacement bearings and re-located extended breather tubes. For the ultimate in transfer case upgrades, look to the USA for twin stick conversions, as well as dual-transfer case adaptions and complete aftermarket units made by companies such as Atlas and Marlin.

TRANSMISSION

WHAT ARE THEY: Transmissions or gearboxes provide alternating gear ratios, allowing for faster vehicle speed, without the need for your engine to rev at a ridiculous rate. Gearboxes also allow four-wheel drives to crawl in technical or steep terrain and use more momentum on high-speed scenarios like sand or corrugated dirt roads.

WHY THEY BREAK: Driver abuse, too much power, poor gear change techniques and worn out clutches will kill gearboxes. The biggest culprit again though is heat, which is why it’s important to have regular oil changes. Keeping water out is equally important, so if there is an external breather tube on your gearbox, you should consider extending it to higher ground, such as the engine bay.

HOW TO UPGRADE THEM: A larger external transmission cooler for automatic gearboxes reduces heat and extends oil life. This is a clever idea for those who tow large loads or see regular off-road activity. For the more hardcore crowd with older gearboxes, look into stronger input and output shafts, which offer a larger contact patch compared to smaller stock units.

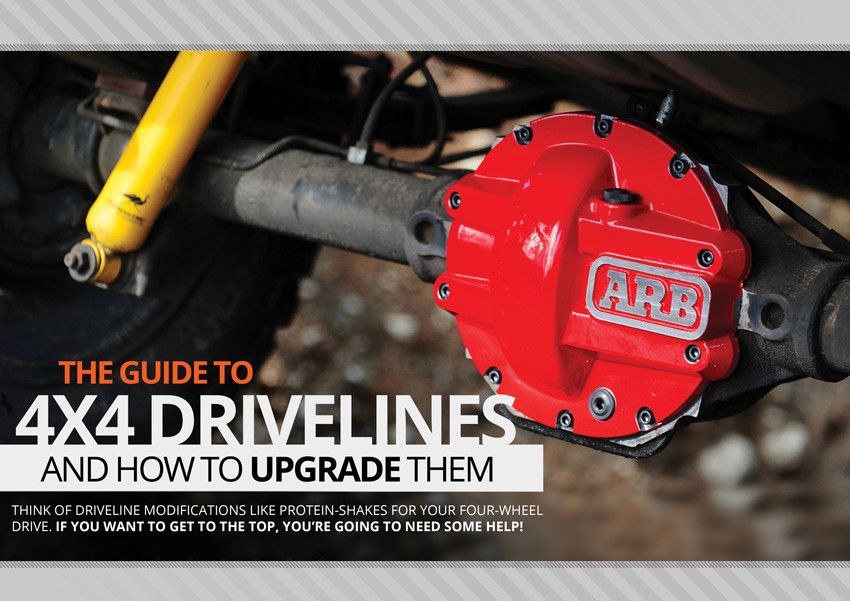

DIFFERENTIALS

WHAT ARE THEY: Differentials are located in your axle housing and allow for variances in wheel speed while cornering. This is necessary as the inside wheel spins slower than the outside wheel when turning. Without a differential, your four-wheel drive would have to slide around corners… and that’s not going to be good for tyre wear, among other things.

WHY THEY BREAK: Enthusiastic driving, lack of maintenance and water entering the diff through breather tubes can leave you stranded at the worst time. Poor mechanical set-up with incorrect backlash settings or pinion set-up is also just as dangerous. If you have a part-time 4X4 with locking hubs and haven’t used the four-wheel drive system for some time, take care as rust can build up on internal crown wheel and pinions.

HOW TO UPGRADE THEM: There are a few tricks to building stronger differentials. Firstly, solid pinion spacers can be installed to reduce pinion flex, and aftermarket crown wheel and pinions allow for ratio changes and additional strength. Periodic rebuilds replacing bearings and checking backlash and pinion depth settings will see you have years of reliable service from your differentials, too. If you want the best of both worlds, installing a stronger, full-carrier replacement aftermarket locking differential boosts traction while being tougher at the same time.

DRIVESHAFTS

WHAT ARE THEY: Driveshafts connect the transfer case to the differentials, providing drive to the vehicle. Made from a variety of materials depending the strength required, including steel tube, DOM (Drawn over mandrel) seamless tubing, chromoly steel tube, aluminium or even carbon fibre (the current model Mitsubishi Pajero utilises a carbon-fibre rear driveshaft).

WHY THEY BREAK: Too much torque or power can cause them to twist. If they are dropped onto a rock they will usually dent or bend. So essentially you wont have issues with a driveshaft unless you cause it. Having them correctly installed (in phase) and balanced is important for reliable operation, though. Just like wheels, driveshafts need to be balanced to ‘spin true’. Remember, if you lift your four-wheel drive, you have put your driveshaft on a sharper angle too, which places more stress on it.

HOW TO UPGRADE THEM: Bolt-on heavy-duty driveshafts are available for most makes and models, and they can be constructed for custom applications, too. Thicker wall material can be used on new custom items, and you can upgrade to stronger chromoly or carbon fibre (costly, and not as proven for 4X4s). Custom made units are the best bet if you enjoy driving rocky terrain, with the benefit of having larger universal joints installed at the same time for extra reliability and strength. Oh, a fresh set of universal joints goes a long way to ensuring reliability and smooth operation.

Words By Evan Spence

Article from Unsealed